During the rolling process the rollers bow slightly which results in the sheets being thinner on the edges.

General tolerance table for sheet metal.

General tolerances to din iso 2768.

In the above example m and k has defined the tolerance.

Tolerance class is defined as per design requirements and manufacturing capability.

Uncontrolled dimensions contain two different categories of tolerances.

International tolerance grades.

The latest din standard sheet version applies to all parts made to din standards.

Variations on dimensions without tolerance values are according to din iso 2768 mk.

1989 general tolerances part 2.

The tolerance of the depth of the hole shall be defined on the drawing.

2 2 1 when the drawing calls for a hole without tolerance on the hole dimension the tolerance block shall apply.

General tolerance iso 2768 does not specify where to use these tolerances.

General dimensional tolerance of blanking unit mm 1.

Variations on dimensions without tolerance values are according to iso 2768.

Tolerances on thickness for continuously hot rolled low carbon steel sheet plate for cold forming according to en 10111 width mm thickness mm w 1200 1200 w 1500 1500 w 1800 w 1800 th 2 00 0 13 0 14 0 16 2 00 th 2 50 0 14 0 16 0 17 0 19.

And for machined components iso 2768 fh can be used.

And for machined components iso 27 68 fh can be used.

Below are dimensions and tolerances typical of stamped metal components.

2 2 hole diameter tolerances 2 2 1 when a drawing calls for a hole and specifies the hole diameter and tolerance the drawing tolerance shall take precedence.

Sheet metal guage tolerances.

Over 120 to 400 incl.

Over 400 to 1000 incl.

For sheet metal parts iso 2768 mk is used.

By press working from sheet metal and shear from metal plates technical data technical data table 1.

As per design requirements and manufacturing capability tolerance class is defined.

For sheet metal parts iso 27 68 mk is used.

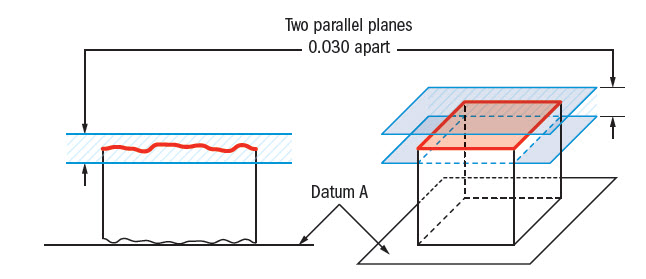

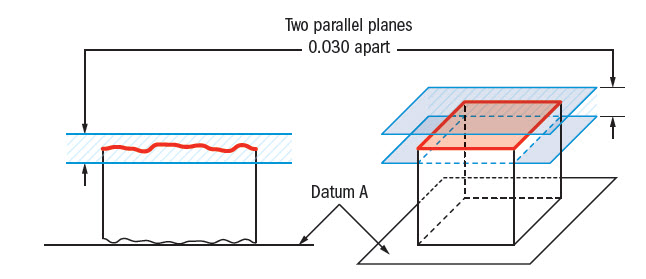

Geometrical tolerances for features without individual tolerance indications.

Of course exceptions apply.

The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the manufacturer s standard gauge which has no inherent tolerances.

Tolerances on thickness according to en 10051 table 2.

General tolerances for linear and angular dimensions din iso 2768 t1 linear dimensions.

Iso 2768 and derivative geometrical tolerance standards are intendedto simplify drawing specifications for.

The tolerances shown are well suited to the progressive stamping process and thus ensure quality and cost effective parts.

Iso 286 table hole tolerances calculator.

All tolerance limits are given in mm.