Because of recent technological advances in application the fully adhered system is becoming the system of choice for roof replacement applications in many areas of the country.

Fully adhered vs loose laid roofing system.

Even if cases of leaking or damage take place repairing such systems is easier and more affordable.

Fully adhered systems are lightweight and ideal for a wide range of building sizes and geometric configurations including high slope applications.

Adhered roofing systems from sika roofing provide an aesthetically pleasing roofing application that delivers superior watertight protection this protection is the result of time tested membranes hot air welded seams and a wide variety of system configurations to match the unique needs of individual building designs.

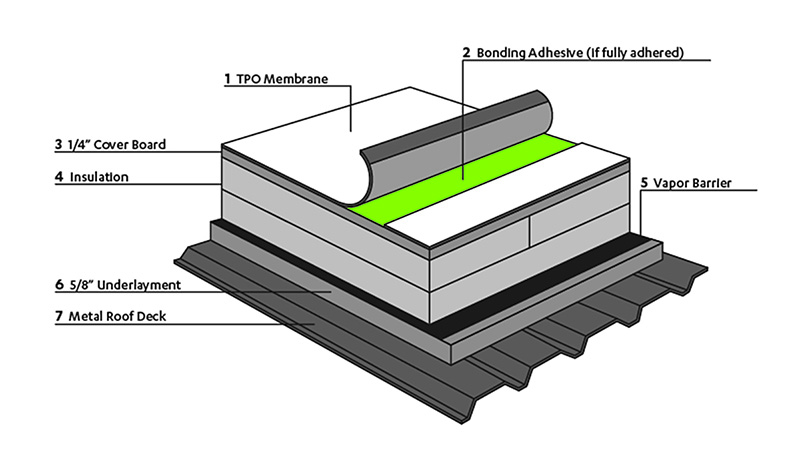

Sheets of insulation are then laid out on the roof system and then either adhered or mechanically fastened with insulation plates and fasteners to the roof decking.

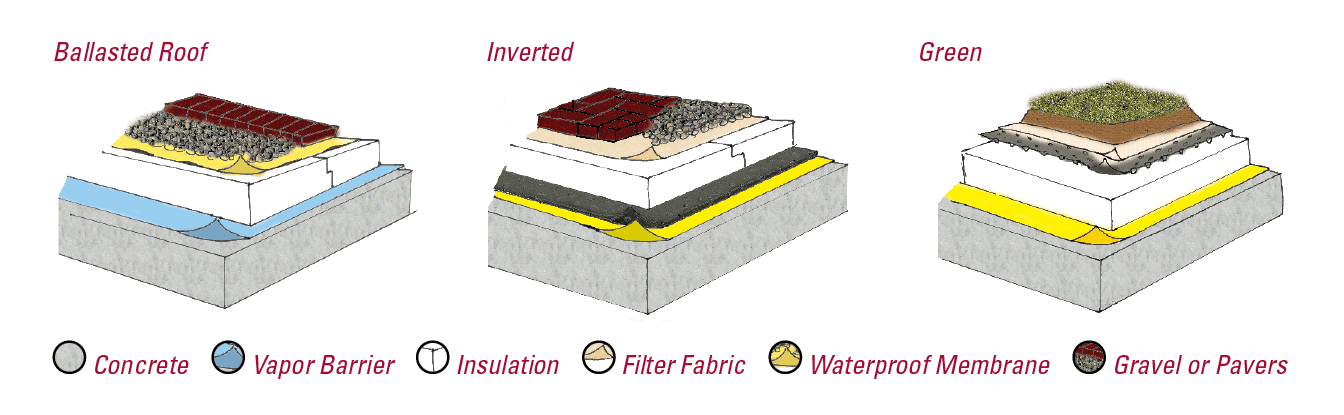

Finally the ballast stone or and pavers are laid down throughout the roof system.

Roofs that are fully adhered are glued directly to the insulation below.

This requires the 4 x8 insulation boards to serve the dual role of insulating and securing the roof to the metal deck which requires far more screws.

The firestone tpo fully adhered system is a lightweight system with outstanding design flexibility it is suitable for contoured roofs roofs with irregular shape and any roof with limited load bearing capacity provided the substrate is compatible with firestone contact adhesives and provides sufficient adhesion.

According to the basic application procedures they differentiate three basic rubber roofing types.

Loose laid air pressure equalization system.

This system should only be used over an air impermeable roof deck or over an air barrier.

Vapor barriers should only be omitted from projects as a recommendation by the design team after careful consideration for the climate zone and building use.

Firestone fully adhered system fas application.

This method is more expensive slower and can lead to additional challenges because large quantities.

The membrane is fully adhered around the roof perimeter but elsewhere the membrane is only loose laid.

All membrane flashing and other detail work is completed.

The rigid insulation is loose laid with a plate and fastener installed here and there to prevent excessive movement.

Epdm adhered systems offers a durable roof system that can be applied on many different types of buildings where the building roof decking provides enough pull out test resistance.

Whether loose laid or fully adhered projects in the midwest should always consider a vapor barrier in the roof system as a first option to protect the roof insulation over the long term.